The SMPA laboratory part of the Reactor Safety and Components Unit (G.I.4) asset, delivers pre-normative materials research to support the safety and reliability assessment of nuclear components. The data generated by SMPA are in support of model development and validation for prediction of design life of new materials and remaining life of service-exposed materials including welded joints. SMPA testing devices are used for the development and adaptation of European codes and standards, as well as for the development of test procedures and instrumentation to achieve simpler, more reliable or non-standard tailored data and estimates of material properties. The SMPA has been part of the team that has developed and published the European Standard EN 10371:2021 on the Small Punch Test Method.

Instruments in SMPA

Structural materials performance

assessment laboratories include the following test machines:

- Universal test machines for tensile, fatigue, fracture, creep-fatigue, slow strain rate tensile (SSRT), creep-fatigue crack growth,

- Small punch, and small punch creep testing.

The lab also has also

- Charpy impact hammers for fracture toughness testing and

- Uniaxial creep test machines.

SMPA is part of the EMMA laboratories and can be accessed through our Open Access program.

Open Access to JRC Research Infrastructures

Facility photos

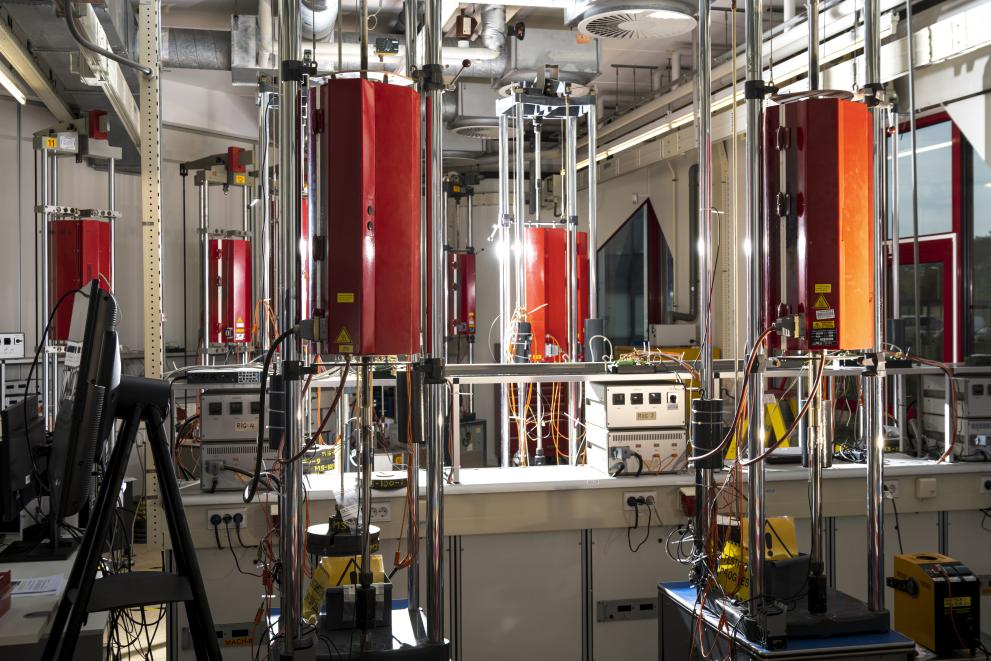

(Uniaxial Creep test laboratory, EU)

You can view additional images of the Structural Materials Performance Assessment (SMPA) laboratory at the EC Audiovisual Service.