On September 28, 2020 the first beam-time at the MONNET (MONo energetic Neutron Tower) Research Infrastructure started in the frame of the JRC Exploratory Research programme.

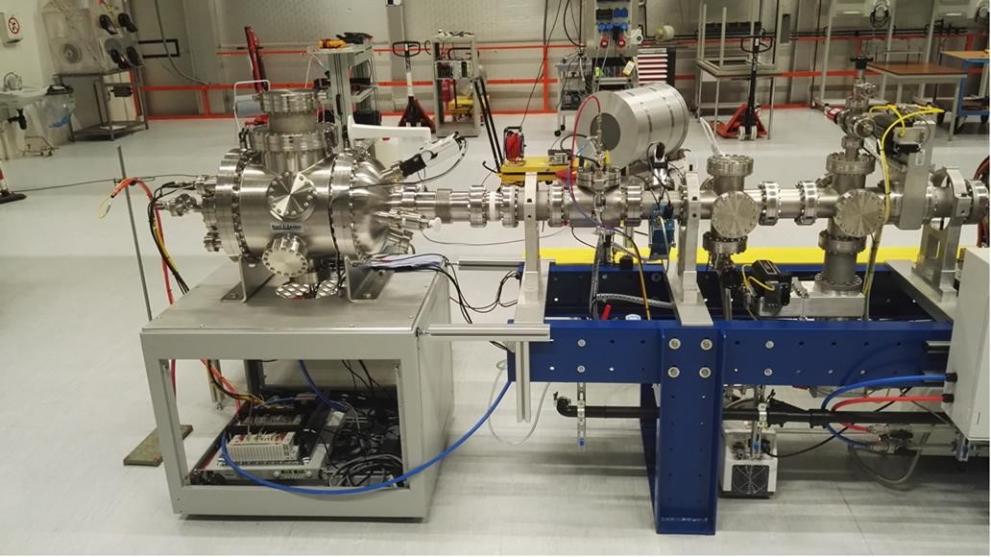

The Exploratory Research project IB4N (Ion Beams For Neutrons) aims at developing within the JRC the capacity to study changes of material properties under irradiation for optimising structural materials, cladding and fuels under levels of irradiation damage relevant to Generation IV reactors and long-term operation of nuclear power plants. Irradiation with neutrons at these levels of damage is not possible with available neutron sources and would activate the samples, requiring all the characterisation to be done in hot cells. Instead, ion beams may be used to simulate the effects of neutron irradiation. With ion beams a very high level of damage can be obtained in a limited time (tens of hours instead of decades) without activating the irradiated samples. The JRC MONNET Research Infrastructure (G.2) offers proton beams with suitable energy and appropriate intensity.

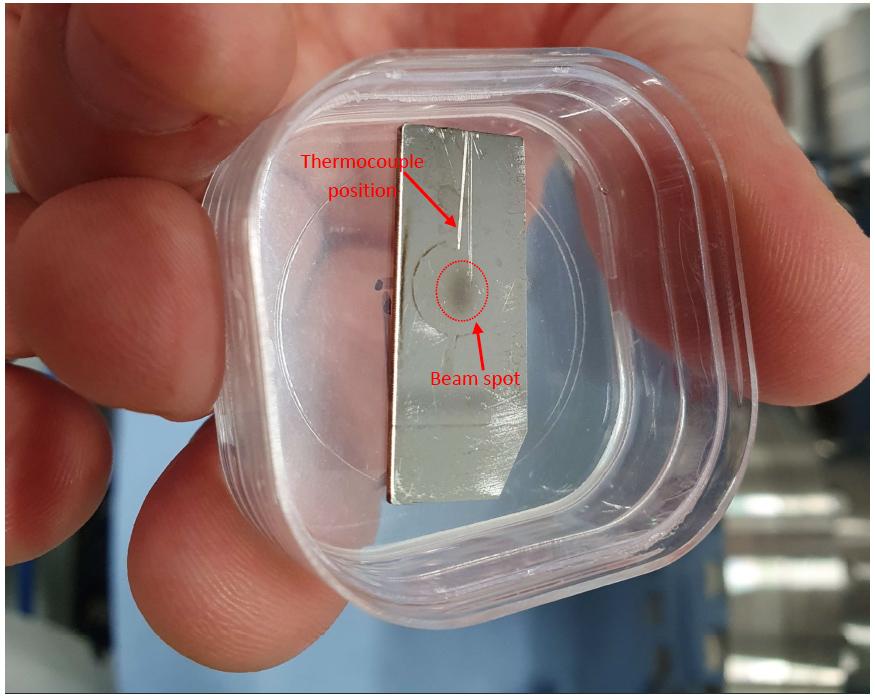

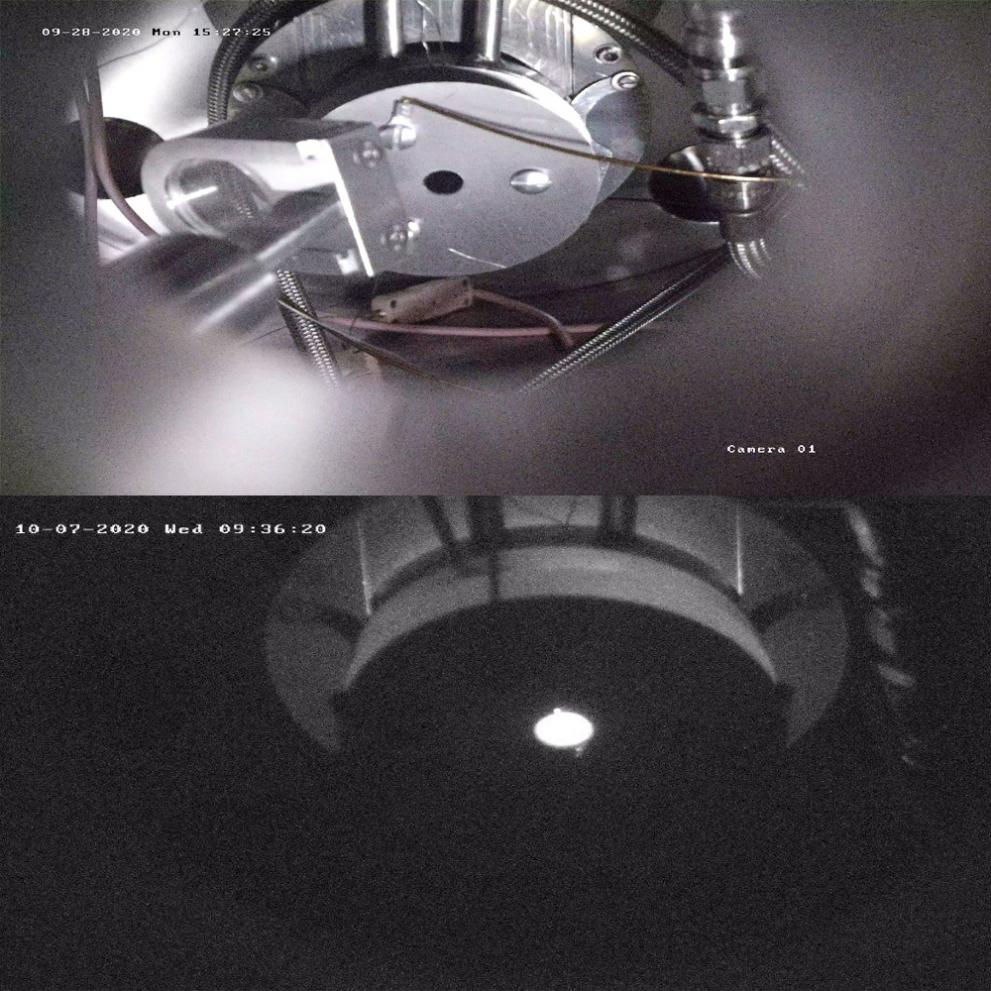

Proton beams with a kinetic energy of 4 MeV were produced impinging on various steel samples, which were kept at a well-defined temperature. Key to a successful experiment was the development of an interface that permitted to control the temperature on the front as well as on the back side of the sample, heating stage and air-cooling supply and the precise monitoring of the proton-beam intensity.

Special thanks go to the MONNET operators and technical support team (Cedric Bonaldi, Thierry Gamboni, Wouter Geerts), for the development and implementation of the control interface as well as the production of stable proton beams, and to the Health Physics Service (Nico Sevenhans, Jeff Goosens). We are grateful to the team of the JRC-GEEL workshop (R.6) for the quick and accurate machining of essential mechanical parts and pieces.

Contact: Stephan Oberstedt (AFM), Peter Hähner (IB4N spokesperson)

Details

- Publication date

- 15 October 2020